Quality Control

Spectrometer Chemical Analysis

A spectrometer measures light properties by breaking it down into wavelengths. In aluminum recycling, it analyzes the chemical composition of materials, detecting the presence and concentration of elements such as copper, zinc, magnesium, and silicon. This ensures that the recycled aluminum meets required specifications. X-ray fluorescence and optical emission are the two types of spectrometers used in the industry. Accurate measurement of chemical composition ensures the quality of recycled aluminum products.

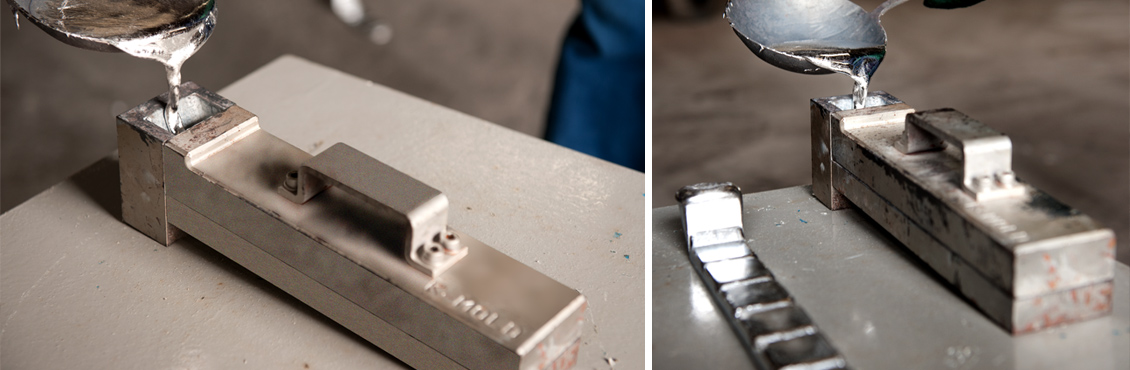

K Mold Test

The K-Mold test is a quality control tool used in aluminum recycling to evaluate the quality of incoming raw materials and ensure consistent production of high-quality aluminum products. To perform the test, multiple samples of the plate are poured from the metal being evaluated, and are immediately fractured by the technician. If the fracture surface contains inclusions or defects, it is considered an “event”. The K-Mold test results are expressed as a ratio of events to sound surfaces, indicating the quality of the aluminum being tested. This test helps to identify and eliminate defective materials, ensuring that only high-quality aluminum is used in the recycling process.

Best Valued Partner, for NOW and FUTURE

Other Links

©2023 Intech Integrated, All Rights Reserved.